MIL-C-13874K

3.13

Each compressor shall be equipped with instruction

plates or diagrams, including warnings and cautions, describing any special or

important procedures to be followed in assembling, operating or servicing the

compressor . I n s t r u c t i o n p l a t e s s h a l l c o n f o r m t o M I L - P - 5 1 4 , t y p e I I I , c o m p o s i t i o n

c, of type I, grade A, class 1 material. Plates shall be attached by screws,

b o l t s , or rivets in a conspicuous, protected location,

3.14 Treatment and painting. The compressor, components, and parts painted in

commercial practice shall be cleaned, created, and painted in accordance with

MIL-T-704, t y p e F or G, a s a p p l i c a b l e . U n l e s s o t h e r w i s e s p e c i f i e d ( s e e 6 . 2 ) , t o p

c o a t color shall be camouflage green 383 conforming to MIL-C-46168 or MIL-C-53039.

3.15

reciprocating.

Type I

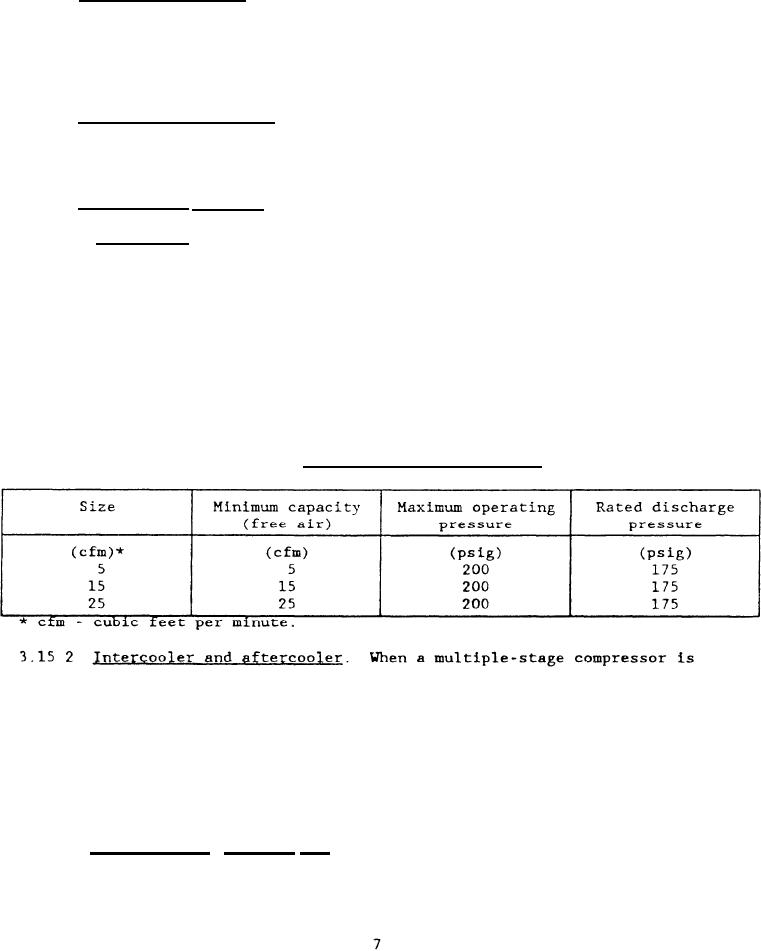

3,15.1 Compressor. The type I compressor shall deliver the capacities of free

air (see 6.5) specified in table I at a pressure of 175 pounds per square inch

g a g e ( p s i g ) , a s determined by the ASME Performance Test Code 9.

T h e components of

the compressor shall be balanced so that when the compressor is operated in

c o n j u n c t i o n w i t h t h e e l e c t r i c m o t o r , v i b r a t i o n s h a l l b e m i n i m i z e d . T h e compressor

shall produce rated capacity at rated pressure for 500 hours in operating periods

of not less than 4 hours. Operating periods of not less than 4 hours (see

4 . 6 . 2 . 4 ) , during high and low temperature tests may be counted (see 4.6.2.5 and

4.6.2.6).

T h e compressor shall nor exceed the contractor's recommended continuous

operating speed. The compressor shall be air cooled. The cylinder heads or

c y l i n d e r a s s e m b l y ( i f c a s t i n t e g r a l l y ) s h a l l b e r e m o v a b l e . T h e intake and exhaust

valves shall be removable. A fan shall be provided for cooling.

TABLE X.

Compressor characteristics.

furnished, an intercooler shall cool the air between the pressure stages and shall

be located so as to be cooled by the airblast from the fan. A spring-loaded-type,

pressure-relief valve shall be installed between the pressure stages to protect

the low-pressure cylinder in case of failure of the high-pressure cylinder valves.

The temperature measured at the discharge of the air receiver shall not exceed

a m b i e n t plus 100 0 F a t a p r e s s u r e o f 2 0 0 p s i g .

If necessary to meet the

temperature requirements specified herein, an aftercooler may be provided between

the last stage of the compressor and the air receiver tank. Aftercooler shall be

air cooled.

3.15.3 Pressure tubing and fitting.

All pressure tubing and fittings shall be

rated to withstand 1-1/2 times their normal working pressure.

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business